Short answer: Commercial air conditioning costs can be slashed by fixing controls, right-sizing equipment, and adding retrofits like VFDs and economizers. In Las Vegas, prioritize peak demand management, high ambient-rated equipment, and dust-resistant designs to control both first cost and long-term energy bills.

What can change commercial air conditioning cost

- System type, efficiency rating (IEER), and controls integration

- Building size, cooling load, and zoning requirements

- Las Vegas-specific factors (high ambient heat, dust loading, peak demand charges)

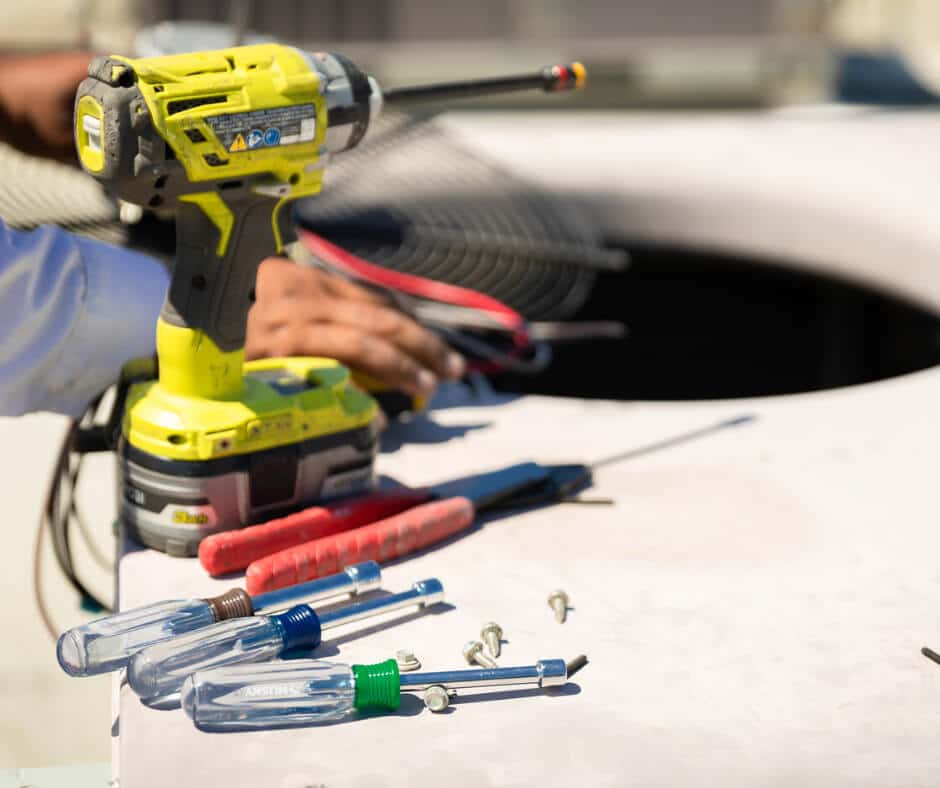

- Installation complexity (rooftop access, crane work, duct modifications)

- Maintenance frequency and filter replacement schedules

- Peak season vs. off-season installation timing

- Utility rebates and incentive programs

> By: The Cooling Company

Start with controls, right-sizing, and preventive maintenance to cut energy and failures fast. Add economizers, VFDs, and commissioning to lock savings and spot problems early. Review incentives and require an engineered load calc on larger jobs to avoid oversizing and costly change orders before peak season. (DOE Better Buildings HVAC)

Las Vegas Context: Commercial buildings in Las Vegas face extreme conditions that significantly impact air conditioning costs. Summer rooftop temperatures exceed 140°F, requiring high ambient-rated equipment. Desert dust loads filters faster, increasing maintenance costs. Monsoon season (July-September) adds humidity load. Peak demand charges during afternoon hours (2-6 PM) can double energy bills if systems aren't properly controlled. Acting before peak season (May-September) allows scheduling crews, claiming incentives, and testing controls in milder weather, avoiding costly emergency work during heat waves.

Key Takeaways

Complete these quick wins first to reduce bills and risk before summer peaks. Prioritize control fixes, right-sizing, and commissioning to get fast paybacks. Use incentives and M&V to improve project value and protect budgets over the system life.

- Start with controls, right-sizing, and preventive maintenance for immediate gains.

- Typical installed cost ranges: RTU $1,000–$2,500/ton; VRF $2,000–$4,500/ton; chillers $800–$3,000+/ton.

- Require ASHRAE-based load calculations and include M&V in contracts to verify savings.

Why reduce commercial cooling costs now?

Commercial cooling drives a big share of utility bills in warm months. Businesses face higher rates and summer demand charges. Acting now avoids mid-season failures that force costly emergency work and tenant complaints. For a cost overview, see our commercial AC unit cost guide.

Taking steps before peak season is cheaper than repairs later. You can schedule crews, claim incentives, and test controls in mild weather. That timing cuts downtime and reduces the chance of expensive rooftop crane work during high demand.

Las Vegas Specific: In Las Vegas, peak cooling season runs May through September, with the most extreme heat (110°F+) typically in July and August. Peak demand charges occur during afternoon hours (2-6 PM) when temperatures are highest. Acting before May allows you to schedule installations during cooler months (October-April) when labor rates may be lower and equipment availability is better. Pre-season maintenance and upgrades also prevent mid-season failures that can cost 2-3x more due to emergency rates and tenant complaints during heat waves.

What drives commercial AC costs?

Capital expense, installation complexity, and ongoing energy use combine to set total cost. Rooftop units add crane and curb costs while central plants add pumps, towers, and piping. Controls and BAS integration often change both capex and operating costs.

Fuel choice and run hours matter a lot. High-hour sites like data centers or hospitals spend more on energy, so efficiency upgrades pay faster. Track these drivers to see which measures give the best return.

How much energy do commercial buildings use for HVAC?

HVAC often uses about one third of a building’s total energy. Run hours and climate change that share for certain building types. Retail stores, labs, and health care can exceed that share due to long runtimes.

Measure runtime hours and peak demand to build a realistic energy baseline. Use interval meter data or BAS trends for a clear picture before you size upgrades or claim savings. (DOE Better Buildings HVAC)

When is an engineered load calculation required?

Require an ASHRAE-based load calc for systems over 20 tons or for a change of system type. Complex retrofits, DOAS integration, or envelope upgrades also need precise sizing to avoid humidity issues and cycling problems.

An accurate load calc prevents oversizing and supports correct control strategies. Ask for a signed calc in the RFP and include acceptance criteria tied to commissioning checks.

Which upgrades give the fastest payback?

Controls, commissioning, and targeted fixes usually give the fastest payback. Small fixes often restore lost savings and prevent wasteful operation. Choosing these first keeps cash flow healthy while you plan larger capital projects. Our commercial HVAC maintenance cost breakdown helps you budget for ongoing PM expenses.

Larger replacements like chillers or VRF systems can cut life-cycle costs. They require longer payback windows. Compare run hours, incentives, and maintenance forecasts before deciding on capital equipment.

Can controls and BAS cut commercial bills quickly?

Yes. Optimizing BAS schedules, fixing sensor drift, and tuning sequences often cut runtime and reduce wasted simultaneous heating and cooling. Simple software or logic fixes can return investment in months at high-run sites.

Start with the highest runtime zones and critical setpoints. Then verify changes with BAS trend logs to prove savings and refine sequences for steady operation.

Do economizers help rooftop units in practice?

Economizers can reduce compressor runtime by using cool outside air when conditions allow. They work best in dry climates and during shoulder seasons. Dampers and sensors need correct calibration to avoid bringing in hot or humid air.

Test economizer operation under multiple outside air conditions. Confirm minimum OA limits and free cooling hours before depending on them for major savings.

Will variable speed drives reduce peak demand?

VFDs on fans and pumps let motors match speed to load and cut energy. They also smooth startup current and reduce demand spikes that drive utility charges. Payback is fast on equipment that runs many hours per year.

Inspect motor condition, belts, and control wiring before adding a VFD. Poor mechanical condition can reduce the expected savings or raise maintenance needs. (DOE Better Buildings HVAC)

Which system types yield biggest lifecycle savings?

Systems with higher up-front cost often win over their life when they fit the building profile. Variable-speed chillers, heat-pump VRF, and well-controlled central plants usually lower total cost for high runtime loads.

For a detailed cost breakdown, see our HVAC pricing guide.

Match equipment type to hours, zoning needs, and service capacity. Avoid generic choices that ignore building use. Use lifecycle models with realistic kWh rates and maintenance estimates.

Use our energy savings calculator to estimate your potential savings.

Which equipment has the lowest lifecycle cost?

For large buildings, water-cooled chillers paired with efficient towers and modern controls often give the lowest lifecycle cost. Their efficiency holds up over many runtime hours and years of operation.

For medium and small buildings, VRF or high-efficiency packaged systems can beat central plants. Compare modeled kW/ton at expected part-load points rather than nameplate ratings alone.

You may qualify for federal tax credits that reduce your upfront cost.

How do chillers compare to packaged rooftop units?

Chillers excel with continuous, large loads and central distribution. They need towers, piping, and pumps, which add maintenance and space needs. Packaged RTUs cost less to install per ton and are simpler to swap out.

Choose chillers when loads are steady and large. Pick RTUs for single-zone, rooftop-served spaces or where up-front costs are tightly constrained.

Are VRF and commercial heat pumps cost effective?

VRF systems give good zoning and part-load efficiency. They suit multifamily buildings and offices with varied schedules. Heat-pump electrification helps reduce onsite combustion and can lower lifecycle cost when gas is expensive.

Evaluate VRF for buildings with many small zones. Factor in refrigerant management plans and skilled contractors for service and commissioning. See our commercial HVAC replacement cost guide for detailed pricing.

How to plan a cost effective replacement?

Plan with a clear RFP that requires load calcs, performance specs, and commissioning. Include utility incentive capture and a refrigerant risk plan. These elements reduce surprises and protect budget performance.

Ask bidders for modeled kW/ton at your expected conditions and runtime warranties. Tie final payments to verified commissioning results to ensure you get the promised performance. (DOE Better Buildings HVAC)

What procurement model limits surprise costs?

Design-build or CMAR with clear performance specs often limits surprises. These models let teams coordinate mechanical, structural, and electrical work early. They can reduce change orders and speed delivery compared to low-bid models.

Include holdbacks for commissioning and M&V results so contractors keep schedules and performance top of mind. That practice aligns incentives and avoids finger-pointing after start-up.

How do you write performance-focused specifications?

Specify kW/ton, IPLV targets, and runtime warranties in the contract. Require BAS point lists, controls sequences, and test procedures. Include M&V deliverables to show actual savings.

Clear specs let you compare apples to apples across bids. They also reduce negotiation time and make acceptance criteria objective during commissioning.

Should you require third party commissioning?

Yes. An independent commissioning agent catches installation or control issues that contractors can miss. Third party commissioning validates sequences, checks points, and confirms performance under real conditions.

Add seasonal tests and BAS point-to-point checks to the commissioning scope. That ensures the system works across the year, not just on a single startup day.

How can you lower operating bills right away?

Start with BAS scheduling, simple sensor fixes, and routine maintenance to cut energy without big capital outlay. These moves lower runtime and prevent avoidable failures. They are low cost and high impact for many facilities.

Next, tune start/stop sequences, set setbacks for nights and weekends, and add occupancy control where useful. Measure baseline energy for a clear view of savings after the changes.

Can scheduling and setbacks cut nights and weekends?

Yes. Optimized setbacks and start times avoid conditioning empty spaces and reduce energy use. Savings are largest in buildings with long unoccupied periods, like offices and schools. Avoid resetting occupied zones too aggressively to keep tenant comfort.

Document schedule changes and monitor BAS trends for a month after setup. Use that data to tweak start times and cool-down strategies to balance comfort and savings. (DOE Better Buildings HVAC)

Will occupancy sensors lower cooling demand?

Occupancy sensors can reduce conditioned space during low use periods. They work best with VAV or zoned systems that can isolate areas. Proper placement prevents false triggers and maintains comfort when rooms are used.

Combine sensors with timed setbacks and BAS logic to avoid constant on/off cycling. Validate sensor coverage during commissioning and adjust zones as needed.

Are demand charges affected by AC control strategies?

Yes. Staggered equipment starts, VFDs, and thermal storage can lower peak power and reduce demand charges. For large facilities, demand management can save more than simple energy-efficiency upgrades.

Use interval meter data to find the true peak window. Target that period with load shifting and coordinated starts to get the best financial benefit.

Las Vegas Peak Demand: NV Energy's peak demand charges typically occur during 2-6 PM on weekdays, especially during summer months. A poorly controlled system can spike demand charges by $200-500+ monthly. VFDs on fans and pumps, staggered equipment starts, and BAS scheduling to reduce cooling during peak hours (without sacrificing comfort) can significantly reduce these charges. Some facilities use thermal storage or pre-cooling strategies to shift load away from peak periods.

Decision Checklist: Reducing Commercial Air Conditioning Costs

Use this checklist to prioritize cost-saving measures:

- ✓ Controls audit: Review BAS schedules, sensor calibration, and control sequences for optimization opportunities

- ✓ Load calculation: Require ASHRAE-based Manual J load calc to ensure proper sizing (avoid oversizing)

- ✓ Peak demand management: Evaluate VFDs, staggered starts, and scheduling to reduce demand charges

- ✓ Filter maintenance: In Las Vegas, change filters monthly during peak season due to dust loading

- ✓ Coil cleaning: Schedule professional coil cleaning every 3-4 months to maintain efficiency

- ✓ High ambient rating: Verify equipment can operate at 125°F+ ambient (critical for Las Vegas rooftops)

- ✓ Utility rebates: Check NV Energy rebates for high-efficiency equipment and controls upgrades

- ✓ Lifecycle cost: Compare 10-15 year total cost (equipment + energy + maintenance), not just first cost

- ✓ Pre-season timing: Schedule installations and major maintenance during October-April when possible

Ready to cut your commercial cooling costs?

If you operate in Las Vegas, call The Cooling Company at (702) 567-0707 to schedule a site assessment. Our NATE-certified techs understand the unique demands of desert climate operation and can:

- Inspect loads, controls, and incentives to build a verified savings plan

- Evaluate peak demand management strategies to reduce energy bills

- Recommend equipment optimized for Las Vegas conditions (high ambient heat, dust, peak demand)

- Identify quick payback retrofits that reduce costs immediately

- Provide fast proposals and commissioning support

We serve Las Vegas, Henderson, and North Las Vegas with comprehensive commercial HVAC services. Outside our area, ask for NATE-certified technicians and require an ASHRAE load calculation in your RFP. That ensures qualified techs and a well-sized system. Then compare proposals by lifecycle cost, not just lowest bid.

How to request a site assessment?

Las Vegas-area owners should call The Cooling Company at (702) 567-0707 to book a site visit. The team brings BAS logs, metering tools, and incentive knowledge. Expect a written scope with prioritized measures and a clear path to verified savings that factors in Las Vegas-specific conditions like peak demand charges and high ambient heat.

If you are outside Nevada, ask potential contractors for NATE certification, ASHRAE load calcs, and past M&V reports. Those items show the firm can size, install, and verify complex systems correctly.

What should a site assessment cover?

A complete site assessment inspects runtime hours, BAS sequences, refrigeration charge, VFDs, and economizer function. It also checks ductwork, insulation, and rooftop curb conditions. The assessor should list low-cost fixes first and capital projects second.

Las Vegas Specific: In Las Vegas, site assessments should also evaluate peak demand patterns, high ambient heat impacts on equipment performance, dust loading on filters and coils, and monsoon season humidity management. Request a written report with estimated savings, payback, and likely incentives (including NV Energy rebates). Use that report to build a procurement plan tied to commissioning and M&V steps.

Contact and next steps

For Las Vegas-area projects call The Cooling Company at (702) 567-0707 for fast responses, incentive help, and verified savings plans. The team helps with proposals, commissioning, and M&V to protect your budget and assure performance in Las Vegas, Henderson, and North Las Vegas. Our commercial HVAC specialists understand desert climate challenges and can help you reduce both first cost and long-term energy bills.

If you are out of area, require NATE-certified techs, ASHRAE load calcs, and M&V deliverables when you issue an RFP. Those requirements help you compare firms on quality and verified performance.

Local Essentials and Challenges for Las Vegas

Las Vegas commercial cooling faces intense rooftop heat, long runtime hours, and demand charges that reward good controls. High‑ambient equipment and dust‑resistant filtration reduce mid‑summer failures. Planning for monsoon humidity and peak windows helps avoid comfort swings and demand penalties.

Cost Drivers That Move the Total

- Equipment type and IEER ratings at part load

- Controls scope, BAS integration, and commissioning depth

- Roof access, curb changes, and crane mobilization

- Filter strategy and coil protection for desert dust

- Utility rebates and demand management requirements

Decision Guidance for Owners and Facility Managers

Compare proposals with a lifecycle lens: demand charges, runtime hours, and maintenance frequency drive long‑term value. Require a documented load calculation, verify high‑ambient ratings for rooftop units, and plan for staged starts or pre‑cooling to reduce demand spikes.

Prevention and Maintenance Priorities

Consistent maintenance is the fastest way to lower operating cost. Change filters monthly during dust season, clean coils quarterly, and verify economizer operation in shoulder months. Track kW/ton and complaint logs to catch issues before peak season.

Neighborhood Coverage for Commercial Cooling

We support commercial properties across the valley, including:

- Downtown Las Vegas

- Summerlin South

- Spring Valley

- Paradise

- Enterprise

- Henderson

- North Las Vegas

Trust Signals and Guarantees

- Serving Las Vegas since 2011

- 55+ years combined experience

- Licensed, EPA-certified

- BBB A+ rated

- Lennox Premier Dealer

- 100% satisfaction guarantee

Find Us on the Map

Share This Page

About The Cooling Company

The Cooling Company has been serving the Las Vegas valley with professional HVAC services for over a decade. Our team of licensed, NATE-certified technicians specializes in air conditioning repair, heating system maintenance, and complete HVAC installations. We're committed to providing honest, reliable service with upfront pricing and a 100% satisfaction guarantee on all work performed.

- Phone: (702) 567-0707

- Reviews: 4.9/5 stars (500 reviews) - See reviews

Service Areas

We proudly serve homeowners and businesses throughout the Las Vegas metropolitan area, including Las Vegas, Henderson, and North Las Vegas. Our service technicians are available for same-day appointments in most areas, with emergency service available 24/7 for urgent HVAC issues.

References

- U.S. Department of Energy (Energy.gov) (accessed 2026-01-03)

- U.S. Environmental Protection Agency (EPA) (accessed 2026-01-03)

- ASHRAE (Standards and guidance) (accessed 2026-01-03)

- ENERGY STAR (Heating & cooling) (accessed 2026-01-03)

Need HVAC Service in Las Vegas?

The Cooling Company provides expert HVAC service throughout Las Vegas, Henderson, and North Las Vegas. Our licensed technicians deliver honest assessments, upfront pricing, and reliable results.

Call (702) 567-0707 or visit commercial HVAC, AC repair, maintenance, or installation for details.