Short answer: Condenser fan motors in Las Vegas fail when the outdoor unit overheats, often due to desert dust, extreme heat, or worn bearings. Typical repair costs range from $100-1,000, averaging around $416. Symptoms include fan not spinning, warm air indoors, or unusual noises. Early diagnosis can prevent costly compressor failures.

For more information, see our guide on AC troubleshooting guide.

For more information, see our guide on common HVAC problems.

What can change condenser fan motor failure risk or repair costs

- System age and maintenance history

- Desert dust and debris accumulation

- Extreme heat exposure and long run times

- Dirty condenser coils increasing motor load

- Capacitor condition (weak caps stress motors)

- Electrical issues and voltage fluctuations

- Physical damage from debris or weather

Las Vegas-Specific Condenser Fan Motor Challenges

- Extreme heat: Summer temperatures exceeding 110°F push motors to design limits, accelerating wear

- Desert dust: Fine particulate matter infiltrates motor housings and accumulates on fan blades, forcing motors to work harder

- Long run times: AC systems run 8-12 hours daily from March through October, reducing time for motor cooling between cycles

- Monsoon season: Sudden dust storms can coat fan blades instantly, causing immediate imbalance and stress

- High energy costs: Failing motors increase energy consumption, impacting monthly bills during peak cooling season

What A Condenser Fan Motor Does In Your AC System

Where The Condenser Fan Motor Lives Outside Your Home

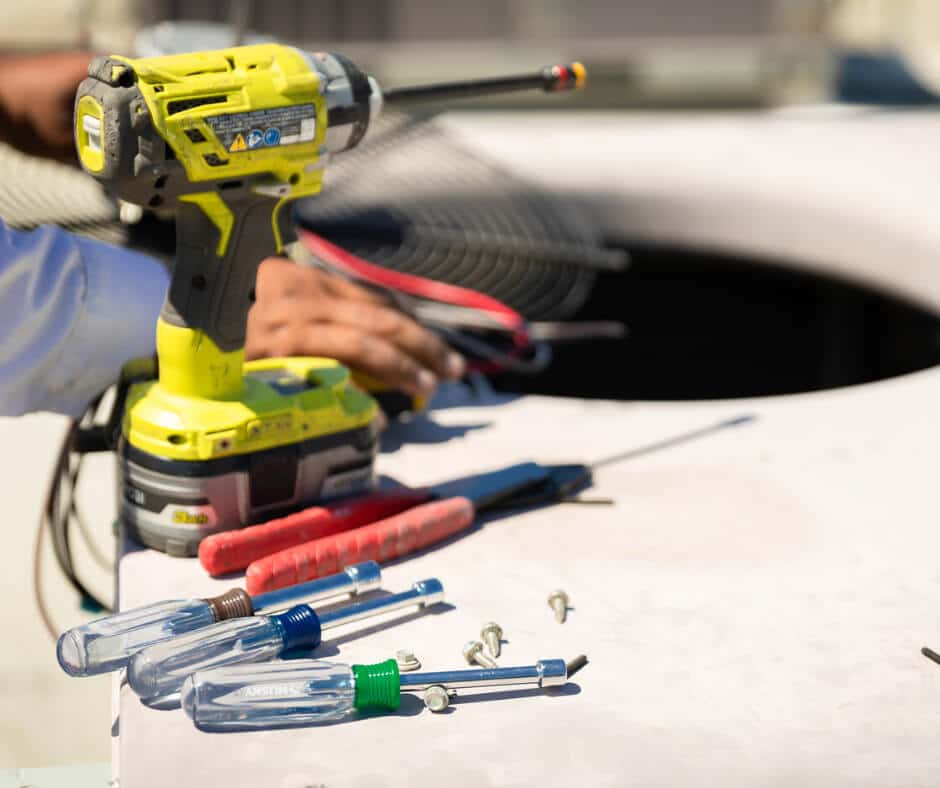

The condenser fan motor sits in the outdoor unit, often called the condensing unit, usually on a concrete pad along the side or back of the home. When looking down into the top grille, that visible fan blade is attached directly to the condenser fan motor shaft. The motor itself is mounted just beneath the top cover, with wiring feeding back into the electrical compartment and control board. This placement is by design. The motor must pull large volumes of outdoor air through the condenser coil that wraps around the unit’s perimeter. Its exposure to full sun, blowing sand, and monsoon dust is part of the job description, which is why condenser fan motors in Las Vegas endure harsher conditions than similar equipment in milder climates.How The Condenser Fan Motor Helps Remove Heat

The air conditioner’s core task is moving heat from inside the house to the outdoors. Indoor air passes over the evaporator coil, where refrigerant absorbs that heat. The warmed refrigerant is then pumped outside to the condenser coil. The condenser fan motor forces outdoor air across that hot coil, carrying away the absorbed heat and allowing the refrigerant to cool and condense back to a liquid. Without sufficient airflow from the condenser fan, the outdoor unit effectively suffocates. Head pressure in the system rises, the compressor works harder, and the entire refrigeration cycle becomes less efficient. Over time, that extra strain accelerates wear on both the motor and compressor, turning a ventilation problem into a full-system reliability risk.Why The Condenser Fan Motor Matters In Las Vegas Heat

Las Vegas summers push outdoor equipment near its design limits. When the condenser fan motor cannot keep up, refrigerant pressures climb rapidly, and safety controls may shut the system down to protect the compressor. During extended heat waves, even a slightly weak motor can mean the difference between steady cooling and repeated nuisance shutdowns in the late afternoon. The local combination of extreme temperature, dusty air, and long daily run times means the condenser fan motor is not just another component; it is the front-line defense keeping the system from overheating hour after hour. This is why small changes in fan performance, such as slower starting or intermittent stopping, tend to show up quickly as comfort issues indoors.How The Condenser Fan Motor Works With The Compressor

The compressor and condenser fan motor start together when the thermostat calls for cooling. The compressor pressurizes and circulates refrigerant; the fan motor ensures that refrigerant can reject its heat outdoors. Many homeowners first notice trouble when the compressor hums, but the fan fails to spin, or when the fan runs but the compressor short-cycles and shuts off due to high temperature. In a healthy system, these two components operate as a coordinated pair. If the fan underperforms, the compressor compensates for a while by working harder, which draws more current and creates more internal heat. Left unresolved, what began as a relatively simple fan problem may evolve into a compressor failure, an order of magnitude more expensive than a motor replacement.Common Terms Technicians Use For The Outdoor Fan Motor

During service calls, technicians may use several interchangeable terms: “condenser fan motor,” “outdoor fan motor,” or simply “fan motor.” All refer to the same part in a standard split air-conditioning system. Confusion sometimes arises because there is also a separate “indoor blower motor” in the furnace or air handler, which circulates air through the ductwork. Clarifying which motor is in question-indoor versus outdoor-helps avoid miscommunication about symptoms, repair options, and pricing when discussing quotes or maintenance plans.When Homeowners Usually Hear About Condenser Fan Motors

Homeowners rarely think about the condenser fan motor until there is a noticeable failure or an annual tune-up report notes wear or noise. Typical trigger points include the outdoor unit making new sounds, the fan blade not moving even though the thermostat is set to cool, or a technician flagging oil leakage or wobble in the shaft bearing during inspection. Because the motor’s job is continuous but quiet, it tends to be invisible until something changes. Recognizing early signs can turn an emergency summer breakdown into a scheduled repair during a cooler spell.Condenser Fan Motor Versus Indoor Blower Motor At A Glance

The condenser fan motor lives outside and cools the refrigerant; the indoor blower motor lives inside and moves conditioned air through the ducts. A failing indoor blower typically shows up as weak airflow from supply vents, noisy operation indoors, or no air movement even though the outdoor unit runs. A failing condenser fan motor, by contrast, often causes the outdoor unit to overheat and the indoor air to feel warm despite some airflow. Understanding which motor is misbehaving is important because costs, parts availability, and repair urgency can differ substantially.Why Condenser Fan Motors Fail More In Desert Climates

Desert climates punish mechanical components with large temperature swings, intense solar radiation, and airborne dust. The lubricant in motor bearings can degrade faster when exposed to sustained heat. Dust and sand infiltrate motor housings and accumulate on fan blades and condenser coils, forcing the motor to work harder for the same airflow. These combined factors cause outdoor motors in Las Vegas to experience more hours of high-stress operation each season compared with identical equipment in cooler, less dusty regions. Proactive maintenance and timely replacement, rather than waiting for total failure, become especially prudent strategies in such environments.Quick Safety Reminder Before Inspecting The Outdoor Unit

Before approaching the outdoor unit to look for obvious signs-like a non-spinning fan blade-power should be turned off at the breaker panel or the outdoor disconnect. The condenser contains high-voltage components and capacitors that can store energy. Removing debris from around the unit or observing the fan through the top grille is generally safe with power off, but opening access panels or testing electrical parts is work for a licensed technician. This simple precaution protects both personal safety and any existing equipment warranties. Homeowner takeaway: the condenser fan motor is the outdoor workhorse that keeps refrigerant pressures under control, and in Las Vegas conditions it carries an unusually heavy load.

Common Symptoms Of A Bad Condenser Fan Motor

Outdoor Unit Humming But Fan Blade Not Spinning

A classic warning sign is an outdoor unit that hums when the thermostat calls for cooling, but the fan blade remains still. The compressor may be trying to start, generating the humming sound, while the fan motor either lacks the torque to begin spinning or is blocked by a seized bearing. Left in this state, internal thermal protection may trip to prevent further damage, but repeated hot restarts are not healthy for the compressor. Homeowners sometimes mistake this for a “dead” air conditioner when in reality one key moving part has failed to start. That distinction is important when deciding between repair and replacement options.Fan That Starts With A Push Then Stops Again

Another symptom often reported is a fan that can be started temporarily by gently pushing the blade with a non-metal object through the grille. If the fan spins up but then slows and stops again, either the motor is weak or the run capacitor that helps it start and run has failed. Capacitors store and release energy to give motors an initial boost; when they deteriorate, motors struggle to start and quickly overheat. Because a failed capacitor can mimic motor failure, many reputable sources note that replacing a faulty capacitor, typically in the mid-hundreds of dollars range, is often significantly cheaper than installing a new motor itself, with estimates for capacitor replacement commonly falling between $150 and $400. Correct diagnosis saves unnecessary spending.AC Running But Blowing Warm Or Barely Cool Air Inside

If the indoor blower runs and some air flows from the vents, but that air is room temperature or only slightly cool, the outdoor fan may not be effectively rejecting heat. Sometimes the fan still spins but at a reduced speed, or it may cycle on and off intermittently while the compressor runs. As a result, refrigerant does not condense properly, and the system’s cooling capacity drops. This symptom can also arise from low refrigerant charge, dirty indoor coils, or duct issues, which is why a thorough system evaluation is essential before assuming the outdoor motor is at fault.Top Of The Outdoor Unit Feeling Extremely Hot

During normal operation, the top of the condensing unit feels warm because it is expelling heat. When the condenser fan motor fails or underperforms, that warmth can escalate into noticeable heat, sometimes hot enough that touching the metal shroud becomes uncomfortable within seconds. This indicates that heat is building up inside the unit, stressing insulation, wiring, and compressor components. Checking the top panel’s temperature immediately after the system has shut down unexpectedly can provide a useful clue for a technician describing the sequence of events.Burning Smells Unusual Noises Or Frequent Short Cycling

Burning odors drifting from the outdoor unit, grinding or squealing sounds, and the system turning on and off in short bursts all belong on the list of possible condenser fan motor symptoms. Burning smells may point to overheating wiring insulation or motor windings. Grinding sounds can signal worn bearings, while rattling or scraping often indicates a loose or bent fan blade contacting the shroud. Frequent short cycling-where the system starts, runs briefly, then shuts off-is the equipment’s way of trying to protect itself from overheating or electrical faults. A failing condenser fan motor is a common trigger for that protective behavior. Homeowner takeaway: if the outdoor fan hesitates, stops, or runs noisily while comfort drops indoors, the condenser fan motor belongs high on the suspect list.What Causes Condenser Fan Motors To Fail

Worn Bearings And Age Related Wear And Tear

Most condenser fan motors rely on sleeve or ball bearings to allow the shaft to spin smoothly. Over years of service, lubrication breaks down, contaminants enter, and metal surfaces wear. The result is increased friction, heat, and noise. Eventually, the motor draws more current, runs hotter, and either trips thermal protection or seizes entirely. Signs of bearing wear include grinding noises, a fan blade that does not coast freely when spun by hand with power off, or visible wobble in the shaft. At that point, replacement rather than repair is usually the most economical path.Weak Or Failed Run Capacitors Stressing The Motor

The run capacitor, a small cylindrical or oval component, works in tandem with the motor by shaping the electrical current it receives. When capacitance drifts out of specification, the motor loses starting torque and must struggle harder to reach operating speed. Over time, this chronic strain overheats the motor windings and shortens its life, even if the capacitor has not yet failed completely. Because a new capacitor typically costs significantly less than a new condenser fan motor, with many replacement ranges for capacitors in the mid-hundreds of dollars, timely testing and replacement of weak capacitors can extend motor life and delay more expensive repairs.Dirty Condenser Coils Raising Head Pressure

When dust, pollen, and yard debris accumulate on the condenser coil, airflow is restricted and heat transfer efficiency plummets. The condenser fan motor must work against increased resistance, and the refrigerant remains hotter leaving the coil. This raises the system’s head pressure, forcing the compressor to work harder and drawing more power through the motor as it tries to maintain airflow. Overextended operation under these conditions acts like running the system uphill every day. Both compressor and fan motor age faster, with failure more likely to occur during extreme weather.Debris Obstructions And Physical Damage To The Fan

High winds can blow plastic bags, leaves, and small branches into the fan opening. Even minor obstructions can block the fan blade or cause it to bend. Once a blade is unbalanced, each revolution places uneven stress on the motor bearings and mounting hardware. Over enough hours, this imbalance shakes components loose and hastens bearing failure. Regularly clearing vegetation from around the unit and visually checking for lodged debris, with power off, reduces the risk of these mechanical stressors.Electrical Issues Loose Connections And Overheating

Loose wire connections create resistance, leading to localized heating at terminals and lugs. Over time, this heat can char insulation and reduce the effective voltage reaching the motor. Undervoltage operation causes the motor to draw more current, again generating excess heat and accelerating insulation breakdown inside the motor windings. Routine maintenance that includes tightening electrical connections and checking for discoloration or heat damage is one of the simplest ways to preserve motor reliability.Oversized Systems Long Run Times And Las Vegas Climate

System sizing affects how often and how long the condenser fan motor runs. In many Las Vegas homes, older or improperly sized systems may run nearly continuously on peak days. Long cycles mean the fan motor spends extended periods at elevated temperature, reducing time for cooling between calls. Conversely, oversized systems with very short cycles can cause more frequent starts, which are the most stressful moments for an electric motor. Combined with rooftop sun exposure and high ambient temperatures, these load patterns help explain why fan motors in desert cities often fail sooner than those in cooler regions.Lack Of Regular Maintenance Visits And Coil Cleaning

Skipping annual maintenance compounds many of the stresses described above. Dirty coils, loose connections, undetected capacitor degradation, and unnoticed bearing noise all quietly shorten motor life. Service visits that include cleaning the condenser coil, verifying capacitor values, lubricating where applicable, and checking motor amperage against nameplate ratings can dramatically reduce unexpected failures. Industry cost analyses consistently emphasize that regular professional maintenance, including yearly HVAC tune-ups, helps extend the life of major components and avoid some of the higher-range repair bills associated with emergency failures, as highlighted in the condenser fan motor cost discussions from Forbes’ HVAC repair guide.Installation Mistakes And Mismatched Replacement Parts

Improper installation can doom a new condenser fan motor from the start. Common errors include using a motor with the wrong horsepower or speed rating, miswiring the motor or capacitor, failing to install a new compatible capacitor when required, or mounting the motor so that the fan blade sits too low or too high in the shroud. Each of these mistakes can cause overheating, noise, vibration, or reduced airflow. When a new motor fails prematurely, careful review of the installation details and part specifications is often the key to preventing a repeat failure with the next replacement, especially in demanding climates. Homeowner takeaway: most condenser fan motor failures trace back to heat, dirt, electrical issues, or misapplied parts-factors that good maintenance and correct installation can largely control.Common Questions or Objections

“Is replacing a condenser fan motor really worth it, or should the whole system be replaced?” For many systems that are otherwise in good condition, a motor replacement remains a mid-range repair rather than a full-system decision point. National cost analyses place the average condenser fan motor replacement around the mid-four-hundreds of dollars, which is described as roughly average compared to other HVAC repairs by Forbes’ breakdown of AC fan motor costs. The age of the overall system, history of compressor issues, and presence of other major problems usually matter more than the motor itself when considering full replacement. “Can a handy homeowner replace the condenser fan motor to save labor costs?” While mechanically minded homeowners may be comfortable changing a fan blade or clearing debris, replacing the motor involves electrical work, capacitor selection, wiring diagrams, and safe discharge of stored energy. Mistakes can damage expensive components or create shock hazards. In most cases, the better balance of safety and reliability comes from hiring a licensed HVAC technician and focusing homeowner efforts on safe tasks like keeping the area around the unit clean and scheduling maintenance visits before peak summer heat. Homeowner takeaway: repair versus replace decisions depend on system age and condition, but for many Las Vegas homes a properly installed condenser fan motor remains a cost-effective way to restore reliable cooling.Prevention Checklist for Las Vegas Homeowners

- Monthly: Visually inspect outdoor unit for debris, vegetation, or unusual sounds

- Quarterly: Clear vegetation and debris from around unit (maintain 2-3 feet clearance)

- Before peak season (March): Schedule professional AC tune-up including motor inspection

- During peak season: Monitor for symptoms (fan not spinning, warm air, unusual noises)

- After dust storms: Inspect outdoor unit and rinse debris if visible accumulation

- Year-round: Keep condenser coils clean to reduce motor load

Decision Guide: When to Call Immediately vs. Schedule Service

Call immediately if:

- Fan blade is not spinning when AC is on

- Burning smells or visible smoke from outdoor unit

- System won't start at all

- Loud grinding or squealing noises

- Outdoor unit feels extremely hot to touch

Schedule service soon if:

- Fan starts slowly or requires a push to begin

- AC running but blowing warm or barely cool air

- System short cycles (turns on/off frequently)

- Unusual noises but system still functioning

- Energy bills have increased significantly

Ready for Reliable Cooling? Schedule Your Service with The Cooling Company

Don't let a faulty condenser fan motor leave you sweating through the Las Vegas heat. The Cooling Company is here to restore your comfort swiftly and efficiently. Our certified technicians are experts in AC repair, AC maintenance, and installation, ensuring your system runs smoothly when you need it most.

See why homeowners trust us — view our industry awards and certifications.

We understand the unique challenges Las Vegas presents—extreme heat, desert dust, and long cooling seasons that stress outdoor components. Our technicians are experienced in diagnosing condenser fan motor issues quickly and accurately, helping you avoid unnecessary costs (like replacing a motor when a capacitor would suffice) and preventing more expensive compressor failures.

With our satisfaction promise and Lennox Premier Dealer status, you can trust in our workmanship and the quality of our service. We offer maintenance plans that include regular inspections to catch motor issues before they become emergencies. Contact Us today to schedule your service and stay cool in the Las Vegas sun.

Share This Page

Need HVAC Service in Las Vegas?

The Cooling Company provides expert HVAC service throughout Las Vegas, Henderson, and North Las Vegas. Our licensed technicians deliver honest assessments, upfront pricing, and reliable results.

Call (702) 567-0707 or visit AC repair, maintenance, heating, or installation for details.