> By: The Cooling Company

Key Takeaways

- Use a room-by-room Manual J load calculation (not a square-foot rule).

- Select equipment with Manual S and verify ducts with Manual D for comfort and efficiency.

- Avoid oversizing: short-cycling wastes fuel and can create uneven temperatures.

Lennox heat pumps move heat between indoor and outdoor air using a reversing valve and refrigerant. They both cool and heat efficiently in Las Vegas when sized and maintained. Common failures include refrigerant leaks, electrical faults, poor airflow, and control errors. Act quickly to avoid compressor damage. For local diagnostics and service options see lennox heat pump las vegas. The.

Lennox Heat Pump Repair Las Vegas: Key takeaways

Lennox systems use a standard refrigeration cycle but add brand-specific controls and matched components. That means the compressor, expansion device, and coils work like other heat pumps, but the control board layout, staging logic, and sensors can differ. Regular filter and coil care prevents many failures. Simple maintenance keeps the unit efficient and helps it meet rated SEER and HSPF. If you are troubleshooting, start with the easy checks: filters, breakers, and thermostat settings. Measure return and supply temperatures and record suction and head pressures to speed diagnosis.

Choosing the right equipment matters. Use a room-by-room Manual J load calculation rather than a simple square-foot rule. Match equipment with Manual S guidance and verify ducts using Manual D. Oversizing causes short-cycling, wasted energy, and uneven temperatures. For service, insist on OEM parts for major components when possible and hire a licensed technician for refrigerant work or major electrical repairs. Many warranties require professional maintenance and registration.

Basic maintenance tips

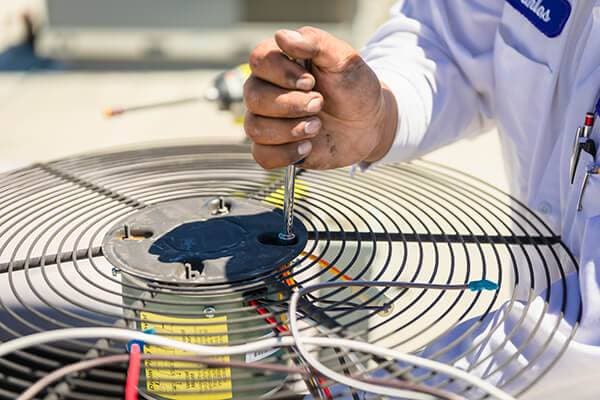

A few simple tasks prevent many failures. Change or clean filters every one to three months during heavy use. Dirty filters reduce airflow and can cause coil freeze-up or high head pressure. Keep plants and debris away from the outdoor unit and clear six to twelve inches of clearance around the condenser. Clean coils gently with a soft brush and mild coil cleaner when needed. Maintain proper airflow to avoid compressor strain.

Annual or semi-annual tune-ups help catch issues early. A technician will check airflow, refrigerant charge, electrical connections, and controls. Keep records of tune-ups for warranty support. Tighten panels and fasteners and inspect condensate drains to prevent leaks and mold growth.

Diagnostic priorities for technicians

A structured diagnostic approach saves time and improves outcomes. Document what the system does and when symptoms occur. Note thermostat settings, outdoor and indoor conditions, and any unusual noises or odors. Measure system operating temperatures and pressures under normal load. Record run times and cycles. These details help the technician focus tests and avoid unnecessary parts replacement.

Always provide model and serial numbers when possible. Matched indoor coils and control boards can matter for parts and settings. A technician will verify correct refrigerant type, check line set sizing, and review control configurations, especially for multi-stage or variable-capacity units.

When to call a pro

Call a certified technician for refrigerant leaks, electrical faults, persistent noise, or defrost issues that you cannot resolve with basic checks. If you see ice on the outdoor coil during heating mode or frequent short cycling, stop using the unit and call for service. Many repairs require EPA certification or specialized tools that are not safe for DIY work.

If the unit is under warranty, avoid unauthorized repairs. Warranty terms often require professional service and proof of regular maintenance. A licensed technician can also test controls, replace OEM parts, and handle refrigerant recovery safely.

What is a Lennox heat pump and how does it work?

A Lennox heat pump moves heat using a closed refrigerant loop. Key parts include a compressor, expansion device, two coils, a reversing valve, outdoor and indoor fans, and controls. In cooling mode the indoor coil acts as the evaporator and the outdoor coil rejects heat. In heating mode the reversing valve flips refrigerant flow so the outdoor coil supplies heat to the indoor space.

Lennox adds brand-specific controls that manage staging, fan speeds, and defrost timing. Many Lennox models use variable-speed blowers or compressors, which change how technicians test and interpret electrical loads. Matched indoor coils and correct refrigerant charge help Lennox units reach their rated SEER and HSPF values.

How do heat pumps differ from AC units?

Heat pumps both cool and heat by reversing refrigerant flow. Air conditioners only cool and require a separate furnace for heating. In mild-winter climates like Las Vegas, a heat pump can provide year-round comfort and reduce the need for gas heating. That simplifies system design but changes failure modes; technicians must consider defrost cycles, reversing valves, and outdoor coil performance in heating mode.

Operational checks for a heat pump include verifying defrost control actions and measuring outdoor coil temperature during heating. AC-only systems do not require these checks, so the testing steps differ.

How does a Lennox model vary from others?

Lennox makes single-stage, two-stage, and variable-capacity compressors. Higher-tier models include improved coils, variable-speed fans, and smarter control boards. These features change diagnostic steps and required tools. Variable-capacity systems use inverters and need electrical and drive diagnostics that are different from fixed-speed compressors.

When replacing parts, match the control board and communication protocol to the indoor unit. Substituting a non-matched coil or board may reduce efficiency or disrupt staging and defrost functions.

What components make up the system?

Key components include the compressor, condenser coil, evaporator coil, reversing valve, expansion device (TXV or fixed orifice), outdoor fan motor, indoor blower motor, and control board. Inside the air handler you will find the filter, thermostat, blower wheel, and safety devices like float switches on the condensate pan.

Each component affects pressures, currents, and airflow. When one fails it can produce symptoms that mimic other failures. For example, low airflow can mimic low refrigerant charge by reducing evaporator heat transfer and causing higher superheat readings. Careful step-by-step testing isolates the true cause.

How to triage common Lennox heat pump faults?

Triage starts with simple, safe checks you can perform yourself. Note odors, noises, run times, and the temperature change at vents. Check filters, breakers, and thermostat settings. Verify that the outdoor unit and registers are unobstructed. These checks often reveal the cause and can save a service call. Never open high-voltage panels unless you are qualified.

If basic checks do not fix the issue, document temperatures and noises for the technician. This documentation helps replicate symptoms and pick the right diagnostic tests. Avoid running the system with obvious mechanical issues that could cause compressor damage.

Why is my heat pump not cooling?

Poor cooling commonly stems from low refrigerant, blocked airflow, or compressor issues. Start with the filter and outdoor coil. Confirm thermostat mode and fan operation. Measure return and supply temperatures to calculate the temperature split. A normal cooling split is typically 16–20°F with good airflow.

If the split is much lower, suspect restricted airflow, dirty coils, or low refrigerant. Low refrigerant often causes the outdoor unit to run longer and the indoor evaporator coil to frost. Record static pressure if possible and provide these readings to your technician.

What causes loud or rattling noises?

Rattles often come from loose panels, mounting brackets, or debris hitting the fan blade. Mechanical growls can indicate worn bearings or failing compressor mounts. Electrical buzzing may point to failing capacitors or contactors. After clearing debris and tightening panels, stop the system if the noise persists and call a technician.

A persistent knocking or hard-start pattern can signal severe compressor problems. Running the unit in that state risks permanent damage and higher repair costs.

Why does the unit short-cycle often?

Short-cycling means the compressor turns on and off too frequently. Causes include oversized equipment, low refrigerant, a faulty thermostat, or bad capacitors. Check thermostat placement and settings first. If the thermostat is near a heat source it can cause false calls for cooling.

If mechanical causes are suspected, have a technician measure pressures and current draw to locate the root cause. Replacing a capacitor or correcting a charge may solve the issue. If oversizing is the cause, replacement with correctly sized equipment is the long-term fix.

What if the outdoor unit freezes up?

Ice on the outdoor coil during heating often means a defrost control or sensor failure. In cooling season, ice suggests low refrigerant or poor airflow. Turn off the system to allow thawing. Then have a technician test defrost cycles, defrost thermostats, and the reversing valve.

Document when the ice appears and how long the unit ran before freezing. That timeline helps technicians diagnose intermittent defrost failings or charge problems. A sample case and repair are documented in lennox defrost board error summerlin.

How to fix condensate drain problems?

Clogged drains cause water backups and indoor leaks from overflow pans. Dirt, algae, and debris commonly block drain lines. Flush the line with white vinegar and run water to check flow. Use a wet-dry vacuum on the outdoor stub to clear stubborn clogs. These steps often clear soft blockages safely.

If the clog recurs or the pan is damaged, a technician should inspect the trap, float switches, and pan condition. Persistent clogs can be due to a damaged trap, collapsed piping, or biological growth that requires mechanical cleaning or anti-microbial treatments.

DIY steps to clear a condensate drain

Turn off the system at the thermostat and power switch. Locate the drain access or cleanout and pour a cup of white vinegar into the line to break down organic growth. Let it sit and then flush with warm water. A wet-dry vacuum at the outdoor stub can draw clogs free. Always confirm flow by running the condensate pump or pouring water into the drain pan.

Avoid using chemical drain cleaners that can damage plastic piping or harm the environment. If the problem persists after DIY attempts, stop and schedule professional service.

When to call a technician for drain issues

Call a tech if water continues to back up, if you detect mold growth, or if float switches are tripping frequently. Also call if the drain piping is damaged, collapsed, or routed improperly. Technicians can inspect pans, pumps, and float switches and replace parts to prevent recurring leaks.

If the overflow has caused water damage or mold, address both the HVAC repair and the building repairs promptly to prevent health issues and further structural damage.

What measurements matter for a proper diagnosis?

Good diagnosis uses temperature, pressure, current, and airflow readings together. Each measurement provides insight into refrigerant charge, mechanical condition, or control operation. Accurate readings under normal load reduce guesswork and lead to effective repairs. Technicians should use thermometers, gauge sets, a clamp meter, and an anemometer for airflow.

Record ambient conditions and operating values. Pressures vary by refrigerant and outdoor temperature. Superheat and subcooling tests confirm charge and metering device function when taken with pressures and line temperatures. Electrical tests check health of motors, capacitors, and wiring integrity.

How to measure temperature split

Measure return air at the grille and supply air at the register after the system has run for about 15 minutes. Subtract supply from return to get the temperature split. A healthy split in cooling is typically 16–20°F with proper airflow and a clean coil.

If the split is low, check for restricted airflow, dirty coils, or low refrigerant. A high split may indicate poor heat transfer at the coil or closed dampers.

What pressures should a tech record?

Record low-side and high-side pressures with the system running and note ambient temperatures. Pressures depend on the refrigerant type and outdoor conditions. Technicians compare readings to expected values for the refrigerant to spot low charge or high head pressure from dirty coils or restricted airflow.

Document both static and running pressures and record these values for trend tracking during follow-up visits.

How is superheat and subcooling checked?

Superheat is checked at the evaporator outlet and shows how fully refrigerant evaporates. Subcooling is checked at the condenser outlet and shows how far the liquid refrigerant cools below saturation. Both numbers help confirm charge and metering device operation when taken with pressures and line temperatures.

Technicians use these readings together. Low subcooling with low pressures often indicates low charge, while high superheat can indicate a starving evaporator or metering device issue.

What electrical tests matter?

Key electrical checks include line voltage, amp draw on compressor and motors, capacitor microfarads, and contactor continuity. Use a clamp meter for running amps and a multimeter for voltage. Loose or corroded connections show high resistance and can cause heat or intermittent failures.

Document all readings. Trending amps and voltages over time helps predict motor or compressor failure before it becomes catastrophic.

When should you repair versus replace a unit?

Decide by weighing age, repair frequency, efficiency gains, and comfort needs. A unit under ten years that needs a modest repair often makes sense to fix. For units older than twelve years, replacement may lower bills and reduce future breakdowns. Consider replacement when the compressor or coil needs major work and the unit is old or uses an outdated refrigerant.

Also factor in duct condition and current SEER. If ducts are leaky or undersized, replacing the air handler and outdoor unit together with proper duct sealing gives better long-term comfort and efficiency. Compare repair cost, remaining life expectancy, and comfort improvements before deciding.

How does unit age affect replacement decisions?

Older equipment faces wear, lower efficiency, and parts scarcity. After about 12–15 years failures become more common and parts may be harder to source. Replacing older Lennox equipment can pay off with lower energy bills and more reliable performance. New systems often include improved humidity control and quieter operation.

If a unit has had multiple major repairs in recent years, replacement may be the more economical choice over the next five to ten years.

What repair cost thresholds justify replacement?

A common guideline is to consider replacement if repair costs exceed half the price of a new unit. Also consider how long the repaired unit will likely last. Major repairs like compressor or coil replacements on an old system often make replacement the better long-term value.

Factor in available rebates, possible efficiency gains, and reduced maintenance on a modern, properly matched system.

Typical Lennox repair costs in Las Vegas and warranty

Repair costs vary by part, labor, and model. Small electrical parts like contactors or capacitors are inexpensive and often quick to replace. Compressors and coils are costly and require significant labor. Labor rates in Las Vegas vary by company and whether service is after hours. Get written estimates to compare repair versus replacement and to see itemized charges.

Lennox offers factory limited warranties that vary by model and part. Warranties often require registration and proof of regular maintenance. Keep tune-up records to support any claim. Authorized Lennox dealers can check warranty status and provide factory parts that keep your coverage valid. Part availability depends on model age and dealer stock.

What are common Lennox warranty terms?

Many Lennox units come with five to ten year limited parts coverage when registered and properly maintained. Higher-end models may offer longer compressor warranties. Warranties exclude damage from neglect or improper installation, so keep service records and proof of routine maintenance to avoid denial of coverage.

Authorized dealers can register units and help you understand any required maintenance schedule. Keep copies of receipts and tune-up records.

How to get fast Lennox service in Las Vegas

When you need same-day help, call a local Lennox dealer who stocks common parts and knows Nevada codes. Provide the technician model and serial numbers plus a clear description of symptoms. That helps them bring the right parts and tools and reduces trips to the shop.

If you live in Las Vegas, Henderson, or North Las Vegas, ask for same-day diagnostics and transparent quotes. Choose technicians with Lennox certification, valid state licenses, and good local reviews. Request proof of certification and insurance. For refrigerant work, confirm the tech is EPA-certified and uses proper recovery equipment.

How to pick and schedule a Lennox-certified tech

Pick a tech with factory training and local experience. Ask for references and ask how they handle warranty work. Confirm they stock common parts or have fast access to Lennox distribution to reduce wait times. When scheduling, request a time window and ask about diagnostic fees and typical response times for same-day service.

Request an itemized estimate that lists parts, labor, and warranty coverage before work begins. Ask how they document repairs and whether they supply before-and-after measurements and photos when applicable.

Need HVAC service help in Las Vegas?

While many homeowners can handle basic HVAC maintenance, some tasks require professional expertise. If you're in the Las Vegas area and need help beyond DIY solutions, The Cooling Company is here for you.

Call (702) 930-8411 to schedule a professional assessment. Our licensed technicians can identify issues that might not be obvious and ensure your system runs efficiently.

About The Cooling Company

The Cooling Company has been serving the Las Vegas valley with professional HVAC services for over a decade. Our team of licensed, NATE-certified technicians specializes in air conditioning repair, heating system maintenance, and complete HVAC installations. We're committed to providing honest, reliable service with upfront pricing and a 100% satisfaction guarantee on all work performed.

- Phone: (702) 930-8411

- Reviews: 4.9/5 stars (500 reviews) - See reviews

Service Areas

We proudly serve homeowners and businesses throughout the Las Vegas metropolitan area, including Las Vegas, Henderson, and North Las Vegas. Our service technicians are available for same-day appointments in most areas, with emergency service available 24/7 for urgent HVAC issues.