> By: The Cooling Company

Short answer: Discover HVAC maintenance tips for Lennox EL Elite rooftop units and compare efficient RTUs to estimate energy savings and get incentive-ready data.

Lennox EL Elite rooftop units deliver higher part-load efficiency and easier service than many older RTUs. Proper sizing, ductwork repair, and controls tuning determine real savings. Expect typical energy improvements when paired with duct sealing and economizers. Verify payback using measured baseline kWh and site-specific install costs. (See DOE Better Buildings HVAC for guidance.)

Key Takeaways

- Start with measured loads and baseline kWh before choosing a rooftop unit.

- Use Manual J, Manual S, and Manual D to size equipment and ducts correctly.

- Pair a high-efficiency RTU with duct sealing, economizers, and commissioning for best savings.

- Get written pre- and post-install measurements to verify performance and qualify incentives.

What is the EL Elite Series and why consider it?

Lennox EL Elite units are packaged rooftop units made for small to light commercial buildings. They use modern compressor options and improved coil designs to reduce runtime and improve part-load efficiency. These units are built with service access in mind, so routine tasks cost less time and labor for technicians.

Owners and contractors pick EL Elite models where easy access and fast repairs matter. Retrofit jobs on tight schedules often use these units. The EL Elite focuses on part-load efficiency because most commercial RTU hours occur at partial load. Fan performance and staged controls further reduce runtime and demand charges when installed correctly.

When is the EL Elite a good match?

Choose EL Elite models when serviceability and part-load performance are priorities. Buildings with moderate cooling needs and many short runtime cycles benefit most from a unit that stages compressors or uses variable fans. If the site already supports BMS integration, EL Elite units that speak common protocols make monitoring and fault detection easier.

Sites with older, hard-to-service RTUs also gain value. The quicker a technician can access filters, fans, and compressors, the less downtime the owner sees. For busy facilities, reduced labor time can be a predictable source of savings over the unit life.

What should you check in the catalog?

Look for IEER and fan kW per 1,000 CFM on spec sheets. IEER gives a practical view of part-load performance while fan kW helps predict real-world electric use. Also verify compressor staging, variable-speed fan options, and whether VFDs are factory-installed or dealer-added.

Check the replacement parts list and warranty terms. A clear, long warranty on major components lowers lifecycle risk. Confirm that common parts are readily available to reduce downtime. Finally, ask for factory fan curves and modeled annual kWh based on your climate and operating hours.

Use our energy savings calculator to estimate your potential savings.

How do you know when to replace an RTU?

Frequent breakdowns, rising repair costs, and poor occupant comfort are the usual signs to plan replacement. Older RTUs often leak refrigerant, have worn compressors, and run inefficiently. If repair bills approach a sizable fraction of replacement cost, replacement is often the better financial choice.

Before deciding, measure current runtime, inlet and outlet temperatures, and electrical draw. A one-week sample under typical conditions gives a useful baseline for payback math. Sometimes targeted repairs, duct sealing, or control upgrades restore enough efficiency to delay replacement.

What operational signs show decline?

Uneven temperatures across zones and long runtimes are common clues. High peak electrical demand or short cycling suggest degraded performance or wrong sizing. Look for oil on panels, sticky controls, or moisture on coils as mechanical signs of trouble.

Check compressor run cycles and defrost performance. Short cycling often points to improper control settings or failing components. Measure supply and return temperatures at multiple points to spot coil or airflow issues.

When do roof logistics push replacement timing?

Roof access, tenant schedules, and planned roof work greatly affect installation cost. If a roof must be opened for other work, combine RTU replacement to avoid repeat crane mobilization. That reduces crane day rates and limits roof traffic.

Plan heavy lifts during favorable weather and coordinate warranties when multiple trades are on site. Consolidating work reduces overall disruption and often lowers total install cost.

How should you size and select an RTU?

Sizing must start from measured or modeled loads, not just building area. Use a room-by-room Manual J load and then Manual S for equipment selection. These standards reduce oversizing, improve humidity control, and lower energy waste.

After selecting tonnage, verify ducts with Manual D and measure static pressure at the existing fan. Match the factory fan curve to site resistance or plan a VFD if the site static is far from factory test conditions. Proper fan selection ensures designed CFM and prevents comfort problems and wasted energy.

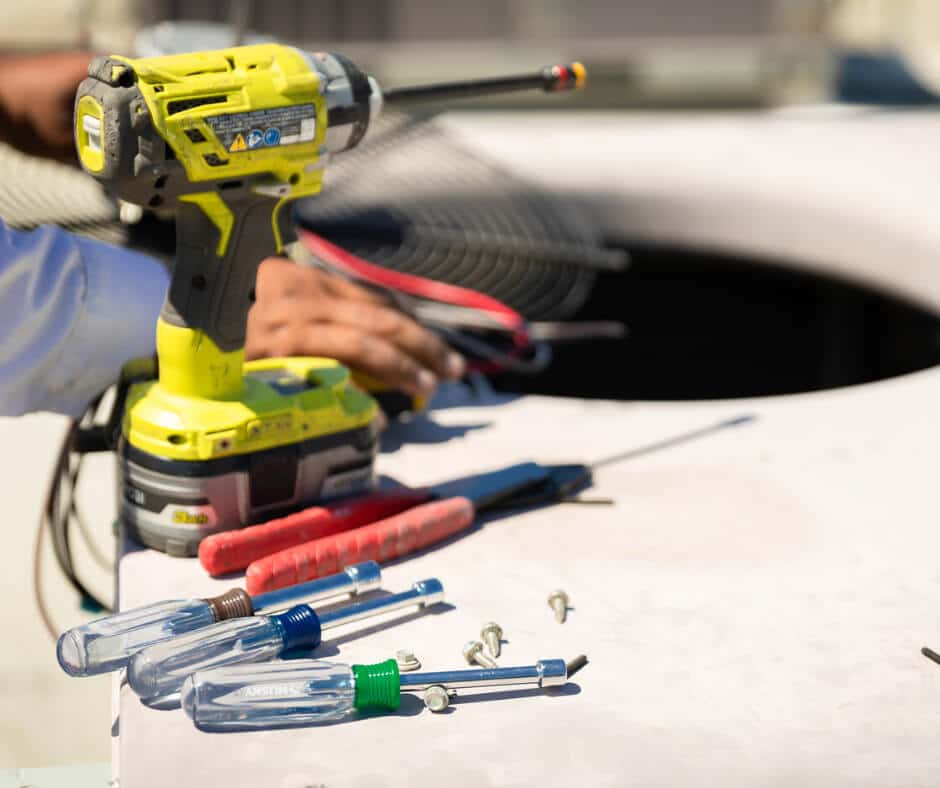

What field checks should you do before replacing an RTU?

Inspect supply and return ducts for gaps, crushed sections, and disconnected seams. Measure CFM at grilles where possible and note static pressure at the fan inlet and outlet. Record curb details, roof clearances, and any obstructions to avoid surprises on install day.

Photograph existing conditions and verify roof penetrations. A small mismatch in curb size or missing curb adapter can delay installation and add cost. Accurate site records improve bid accuracy and reduce change orders.

How does tonnage affect comfort and cost?

Each added ton raises first cost, weight, and electrical service needs. Oversized RTUs cool spaces quickly but can short-cycle. Short cycles reduce dehumidification and can cause comfort issues and higher maintenance.

Slight undersizing makes the unit run longer but often improves humidity control. Balance peak load needs with runtime and moisture removal. Use load calculations to find the right capacity that keeps comfort and cost in check.

What efficiency ratings matter and why?

IEER and EER are the main metrics for RTU efficiency. EER describes steady-state efficiency at a given point. IEER weights performance at several part-load points and better represents typical commercial use. For retrofit decisions, IEER often predicts annual savings better than EER alone.

Fan energy is as important as compressor efficiency. Compare motor kW per 1,000 CFM and look for variable-speed fan options. In many retrofits, a variable fan or a VFD reduces seasonal energy more than a small IEER difference in the compressor.

How does IEER compare to EER?

IEER uses multiple operating points and weighs them to produce a season-representative rating. Rooftop units often spend most hours at partial load, so IEER tends to reflect bill impacts better than a single-point EER value. Always ask vendors for both numbers and for modeled annual kWh estimates.

Manufacturers should also provide assumptions behind IEER to ensure you compare units on the same basis. Differences in test conditions can change the meaning of ratings.

How should you evaluate fan energy?

Request fan motor kW per 1,000 CFM and factory fan curves. If the site static pressure is higher than factory test points, the actual delivered CFM will fall and energy use can increase. Plan to trim fans, change motor design, or install a VFD to meet site resistance.

Documented fan performance prevents surprises. Include fan kW and expected operating points in the proposal. That helps predict real energy use and supports incentive applications that require measured savings.

How much can you save and how to estimate payback?

Measured baseline kWh is the best starting point for any savings estimate. If you know annual cooling kWh, apply a realistic percent savings based on equipment and site measures. Typical replacements of 10–20 year old RTUs often yield 10–30 percent cooling kWh reduction when combined with duct or control fixes.

Include installation scope items in your payback math. Duct sealing, economizer repair, and commissioning often multiply equipment savings. Use sensitivity analysis to show a low, medium, and high savings case so decision makers see the range of outcomes.

What drives energy savings in RTUs?

Controls sequencing, effective economizers, and demand-controlled ventilation are major drivers. Variable fans and smart compressor staging reduce runtime and peak kW. Properly sealed ducts increase the fraction of cooled air that reaches occupants, lowering run time.

Incentives and demand charge reductions also affect project economics. Incentives lower first cost while demand reductions improve operating cash flow, especially for sites with high peak charges.

How do you calculate payback step by step?

Start with current annual cooling kWh. Apply the vendor's or measured percent savings to get estimated annual kWh saved. Multiply saved kWh by the utility rate to estimate annual dollar savings.

Sum installed costs, including ducts, controls, and commissioning. Divide total installed cost by annual dollar savings for a simple payback. Run low and high savings scenarios to show sensitivity and risk.

What installation practices preserve efficiency?

Commissioning is critical. Measure pre- and post-install airflow, static pressure, and power draw. Tune compressors and fan speeds to achieve design CFM and document setpoints in the commissioning report. Require before and after leakage or airflow measurements to support incentives.

Duct sealing and proper curb flashing are common cost-effective fixes. Leaky ducts force longer runtime and increase energy use. Insist on written verification to prove the work and protect long-term performance.

What common installation mistakes cut savings?

Skipping duct sealing, leaving factory fan settings unchanged, and not calibrating economizers are frequent mistakes. These errors reduce delivered savings and can cause comfort complaints. Ask for a detailed scope that includes these checks and a commissioning checklist.

Also avoid leaving temporary lift straps, loose fasteners, or missing weatherproofing. Small installation oversights often cause early failures and warranty disputes.

How to spot poor ductwork or airflow issues?

Uneven room temperatures and frequent complaints often point to leaks or blockages. Use a manometer to measure static pressure and compare measured CFM to design targets. Differences above 10 to 15 percent indicate a need for duct repairs.

Look for dusty registers, unusual noise, or sagging ducts. These physical signs often correlate with measurable leakage or restriction that reduces system efficiency.

How to maintain RTUs for long-term savings?

Change filters based on measured static pressure or at regular intervals to avoid fan power increases. Clean coils and verify refrigerant charge to keep efficiency near design. Dirty coils and improper charge can lower efficiency quickly.

Inspect belts, bearings, and electrical connections. Tighten loose wiring and replace worn belts to avoid energy loss and premature failures. Regular, simple maintenance preserves savings and extends equipment life.

Which controls and economizer options give the best value?

Economizers that provide free cooling during suitable outdoor conditions can cut runtime significantly. Demand-controlled ventilation reduces outside air when spaces are lightly used and lowers conditioning load. Combine economizers and DCV with a rooftop controller that uses open protocols for easy monitoring.

Staged compressors and variable-speed fans reduce short cycling and peak demand. Open protocol controls, such as BACnet or Modbus compatibility, simplify long-term monitoring and limit gateway fees. That helps facility staff manage alarms and trending without vendor lock-in.

What controls and economizers are worth adding?

Prioritize economizers, demand control ventilation, and variable-speed fans for sites with varying loads. These components lower energy use and reduce peak demand. For buildings with predictable occupancy patterns, DCV adds clear savings by matching ventilation to actual needs.

Request modeled performance tied to your baseline hours to see practical benefits. Insist on factory or field commissioning of control sequences to ensure the systems operate as intended.

How should you approach incentives and utility programs?

Check local utility and state incentives for RTU rebates and retrofit programs. Many programs require measured pre- and post-install data, so plan metering and commissioning before work begins. Incentives often make marginal projects clearly justified by lowering first cost.

You may qualify for federal tax credits that reduce your upfront cost.

Demand response and peak management programs can add revenue streams. If demand charges are a major bill component, include peak shaving measures in the scope and ask program managers about measurement criteria and documentation needs.

When should you schedule metering and documentation?

Install metering hardware and collect baseline readings before major work. Record runtime, kW, and CFM under typical conditions for at least a week. These readings support incentive claims and provide a real baseline for payback calculations.

Submit pre- and post-install commissioning reports to incentive administrators. Many programs require signed documentation and measured data to award rebates or performance payments.

See why homeowners trust us — view our industry awards and certifications.

How do demand charges affect project focus?

When demand charges are high, prioritize measures that cut peak kW. Variable-speed fans, staged compressors, and load-shedding strategies often reduce peaks more than small efficiency upgrades. Model both kWh and kW impacts to choose the right package.

Quantify demand savings separately from kWh savings. Some incentive programs offer separate rewards for peak reduction, improving overall economics.

Who should you call to upgrade your RTU?

If you are in Las Vegas, Henderson, or North Las Vegas, call The Cooling Company at (702) 567-0707 for RTU inspection and replacement. The Cooling Company offers on-site measurements, curb verification, and turnkey quotes that include duct repairs and controls integration. Appointments include a written scope and payback estimates.

For readers outside the service area, look for NATE-certified technicians with packaged rooftop experience. Ask bidders for measured baseline kWh, CFM readings, and a written payback estimate that includes installation details. That makes bids comparable across contractors and reduces procurement risk.

What should Las Vegas area owners expect when they call?

Expect The Cooling Company to perform a site survey that documents curb size, roof access, and existing duct condition. The team will take baseline kW and airflow readings and provide a written proposal with incentives, expected savings, and a commissioning plan.

Confirm that the proposal includes before-and-after measurements and a signed commissioning report. Those items protect the owner and help qualify incentive payments.

What should out-of-area buyers require from contractors?

Require documented baseline energy, measured airflow, and detailed shop drawings. Ask for factory fan curves and expected seasonal performance data. Include commissioning and a post-install report as contract conditions to protect long-term performance.

Insist on clear warranty language and access to replacement parts. Contractors should supply an itemized scope, schedule, and a plan for roof protection and curb adaptation during the install.

Ready to act and protect your investment?

Documented commissioning and baseline verification protect both owners and incentive managers. Require installers to provide pre- and post-install readings, a signed commissioning report, and clear warranty terms. Those items also simplify future maintenance and reporting.

If you are in Las Vegas, Henderson, or North Las Vegas, call The Cooling Company now at (702) 567-0707 for an on-site RTU inspection and a written quote. For other areas, ask for NATE-certified technicians and measured baseline data in the proposal. That ensures a fair comparison and reliable savings.

About The Cooling Company

The Cooling Company has been serving the Las Vegas valley with professional HVAC services for over a decade. Our team of licensed, NATE-certified technicians specializes in air conditioning repair, heating system maintenance, and complete HVAC installations. We're committed to providing honest, reliable service with upfront pricing and a 100% satisfaction guarantee on all work performed.

- Phone: (702) 567-0707

- Reviews: 4.9/5 stars (500 reviews) - See reviews

Service Areas

We proudly serve homeowners and businesses throughout the Las Vegas metropolitan area, including Las Vegas, Henderson, and North Las Vegas. Our service technicians are available for same-day appointments in most areas, with emergency service available 24/7 for urgent HVAC issues.

Sources and compliance notes

Follow local building codes and the Lennox installation manual for safe, code-compliant work. Use licensed electricians for service connections and permit-required work. For incentive-funded projects, follow the incentive administrator's measurement and documentation rules to ensure funds are awarded.

- U.S. Department of Energy (Energy.gov) (accessed 2026-01-02)

- U.S. Environmental Protection Agency (EPA) (accessed 2026-01-02)

- ASHRAE (Standards and guidance) (accessed 2026-01-02)

- ENERGY STAR (Heating & cooling) (accessed 2026-01-02)

Consult ASHRAE methods for detailed sizing and selection guidance. Use Manual J for room loads, Manual S for equipment selection, and Manual D for ductwork verification. These standards help avoid common pitfalls and lead to better long-term comfort and cost outcomes.

Related Guides

This aspect deserves careful consideration as you evaluate your options. Understanding the details helps you make more informed decisions. Consulting with qualified professionals provides additional insights specific to your situation. Take time to consider how this information applies to your particular needs and circumstances. Making well-informed choices typically leads to better long-term outcomes and greater satisfaction.

- “lennox hvac model guides” (TCC: Topic)

- “lennox el16xp1 heat pump cost summerlin”

- “lennox el18xv specs henderson”

- “lennox el16xc price las vegas”

Need HVAC Service in Las Vegas?

The Cooling Company provides expert HVAC service throughout Las Vegas, Henderson, and North Las Vegas. Our licensed technicians deliver honest assessments, upfront pricing, and reliable results.

Call (702) 567-0707 or visit HVAC services, HVAC maintenance, heating, or AC repair for details.