Short answer: Commercial HVAC systems in Las Vegas run 14-18 hours a day during peak summer, pushing equipment to its limits when outdoor temperatures hit 115°F. The five most effective strategies to prevent mid-summer failures are: aggressive filter management, pre-season coil and condenser cleaning, refrigerant charge verification, thermostat and BAS scheduling optimization, and a preventive maintenance contract that locks in priority service before the heat arrives.

When you manage a commercial building in Las Vegas, summer is not a season — it is a stress test. From June through September, outdoor temperatures routinely exceed 110°F, rooftop surfaces can reach 150°F or higher, and your HVAC equipment has to bridge that gap every single hour the building is occupied. A 10-ton rooftop unit that coasts through a Phoenix spring will grind through a Las Vegas July. The margin for error shrinks to almost nothing.

We service commercial systems across the Las Vegas Valley — offices on Sahara, retail centers in Henderson, restaurants on the Strip, medical suites in Summerlin. The failure patterns are remarkably consistent. Systems that break down in July almost always show warning signs that could have been caught in April or May. Here are the five maintenance strategies that keep commercial HVAC systems running when the valley hits triple digits.

1. Get Ahead of Filter Replacement — Monthly Is the Minimum

Las Vegas air is hard on filters. Desert dust, construction particulate from the constant building activity, and monsoon-season debris all conspire to clog commercial filters faster than the manufacturer's general guidelines suggest. A filter rated for 90 days in a moderate climate might last 30-45 days in a Las Vegas commercial environment during summer.

Restricted airflow from a dirty filter forces the blower motor to work harder, increases static pressure across the coil, and reduces the system's ability to reject heat. In practical terms, that means higher electricity bills, shorter compressor life, and hot spots that generate tenant complaints. We have seen dirty filters add 15-20% to a rooftop unit's energy consumption in a matter of weeks.

Set a documented filter schedule for every unit in your building. During peak summer (June through September), check filters monthly and replace them when they show visible loading — do not wait for a calendar date if the filter is clearly saturated. After a dust storm or nearby construction activity, inspect filters within 48 hours. Keep spare filters on-site so replacements are never delayed by a supply run. This single habit prevents more mid-summer service calls than any other maintenance task.

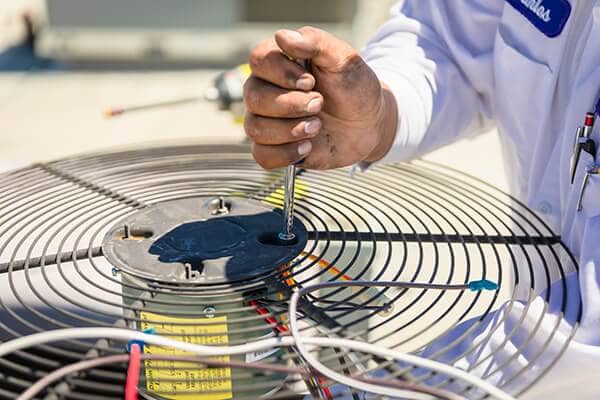

2. Clean Condenser Coils and Clear Rooftop Units Before June

A dirty condenser coil is the fastest way to kill a commercial AC system in Las Vegas. Condenser coils reject heat from the refrigerant to the outdoor air, and when they are coated with dust, pollen, or debris, that heat transfer drops dramatically. The compressor has to work harder to maintain the same discharge pressure, head pressure climbs, and efficiency falls off a cliff. A condenser coil that is just 20% fouled can increase energy consumption by 15-30% and shorten compressor life by years.

Rooftop units in Las Vegas face the worst of it. Sun-baked rooftops push ambient air temperatures around the condenser well above the 110°F reading at street level. Add a layer of dust on the coil fins, and the unit is fighting physics it cannot win. We recommend a thorough coil cleaning in April or May — before the first 100°F day — using a commercial-grade non-acidic coil cleaner and a careful rinse. While you are up there, clear any debris from around the unit, verify that the condenser fan is spinning freely, and check that nothing is blocking airflow to the coil intake.

For buildings near active construction sites or along major roads (think Las Vegas Boulevard, the 215 Beltway corridor, or the Summerlin development areas), consider a second coil cleaning mid-summer. The cost of a cleaning visit — typically $200-$500 per rooftop unit — is a fraction of the emergency repair bill when a compressor fails on a 115°F afternoon. Learn more about our AC maintenance services and what a professional cleaning includes.

3. Verify Refrigerant Charge and Check for Leaks

Refrigerant is the lifeblood of any air conditioning system, and commercial systems in Las Vegas operate at pressures and temperatures that amplify even small charge deficiencies. A system that is 10% low on refrigerant can lose 20% of its cooling capacity. At 20% low, the compressor starts overheating, and failure becomes a question of when, not if.

Las Vegas heat accelerates leak development. Thermal cycling — the expansion and contraction of copper lines and fittings as temperatures swing from 65°F overnight to 115°F by midday — stresses brazed joints and flare connections. Vibration from rooftop units compounds the problem. We find refrigerant leaks in roughly 1 out of every 5 commercial units we inspect during spring tune-ups, and most of those building managers had no idea their system was low.

A proper refrigerant check is not just reading the gauge. A qualified technician measures superheat and subcooling, checks the liquid line and suction line temperatures, and compares readings against manufacturer specifications for the current outdoor ambient temperature. If the charge is low, the next step is a leak search — not just topping off the system. Adding refrigerant without finding the leak is throwing money away; it will leak out again, and R-410A is not cheap ($50-$150 per pound installed, depending on the system).

Schedule refrigerant verification as part of your spring maintenance, ideally 4-6 weeks before peak summer. If a leak is found, you have time to schedule the repair without emergency rates and without your tenants sweating through a 110°F afternoon.

4. Optimize Thermostat Schedules and Building Automation

Thermostat and BAS (building automation system) settings are where commercial buildings bleed money in the summer without anyone noticing. The most common problems we see in Las Vegas commercial buildings:

- No setback schedule: Systems running at full cooling capacity overnight and on weekends when nobody is in the building. An unoccupied office does not need 72°F at 3 AM.

- Too many overrides: Tenants or employees overriding the thermostat to 68°F, forcing the system to fight an impossible battle against 115°F outdoor temperatures. Every degree below 74°F adds roughly 3-5% to cooling costs.

- Simultaneous start-up: All rooftop units kicking on at the same time in the morning, creating a massive peak demand spike that NV Energy charges premium rates for. Staggering start times by 10-15 minutes per unit can reduce peak demand charges by 10-20%.

- Economizer failures: Economizer dampers stuck open during peak heat, letting 115°F air into the building instead of recirculating cooled indoor air. This alone can double cooling costs on the hottest days.

Before summer, walk through every thermostat and BAS schedule in the building. Confirm setpoints match occupancy patterns. Lock out overrides or set limits (no lower than 72°F, for example). Stagger unit start times. Test economizer operation — dampers should be fully closed when outdoor temperatures exceed the changeover setpoint (typically 65-70°F). These adjustments cost nothing and can cut summer cooling costs by 15-25%.

For larger commercial buildings, consider investing in a smart thermostat or BAS upgrade that provides real-time monitoring and alerts. Being able to see that a rooftop unit is running at full capacity at 2 AM on a Sunday is the kind of visibility that prevents waste and catches problems early. See our full range of HVAC services for commercial system upgrades and controls optimization.

5. Lock In a Preventive Maintenance Plan Before Peak Season

This is the tip that separates building managers who scramble from building managers who sleep well in August. A preventive maintenance plan — signed and scheduled before May — does three things that reactive service calls cannot:

- Catches problems early: A failing capacitor, a worn contactor, a belt showing cracks — these are $50-$200 parts when caught during a routine visit. When they fail on a 115°F Saturday, the emergency call alone can cost $300-$500, plus the part, plus the lost productivity or revenue from an uncomfortable building.

- Locks in priority scheduling: Every HVAC contractor in Las Vegas is booked solid from mid-June through September. If you are not on a maintenance plan, you go to the back of the line. Maintenance plan customers get priority scheduling, which can mean the difference between a same-day repair and a three-day wait.

- Creates documentation: A good maintenance plan generates reports on every visit — refrigerant levels, amp draws, temperature splits, filter conditions, component health. That documentation helps you budget for replacements, track efficiency trends, and hold your contractor accountable.

A typical commercial preventive maintenance plan in Las Vegas runs $300-$1,200 per rooftop unit per visit, with most plans including 2-4 visits per year. The pre-summer visit is the most critical: full coil cleaning, refrigerant check, electrical testing, filter replacement, and controls verification. A mid-summer check-in catches anything that has degraded under the heat load. A post-summer visit identifies components that need replacement before the next cooling season.

Explore our maintenance plan options to find the right level of coverage for your building. We work with offices, retail spaces, restaurants, medical facilities, and multi-site portfolios across the Las Vegas Valley.

What a Summer-Ready Commercial System Looks Like

When all five of these strategies are in place, here is what you should expect from your commercial HVAC system during a Las Vegas summer:

- Consistent indoor temperatures within 2-3°F of setpoint, even on 115°F days

- Energy costs that stay within 10% of the previous summer (assuming similar occupancy)

- Zero emergency service calls for preventable failures

- Clean, well-documented maintenance records for every unit

- A contractor who knows your equipment and can respond quickly if something does go wrong

That is not a fantasy — it is what proactive commercial HVAC maintenance delivers in practice. The building managers who invest $2,000-$5,000 in spring maintenance across their rooftop units almost always save $5,000-$15,000 in avoided emergency repairs, reduced energy waste, and extended equipment life over the course of a single summer.

Frequently Asked Questions

How often should commercial HVAC filters be changed in Las Vegas?

During peak summer (June through September), check filters monthly and replace them when they show visible loading. In Las Vegas, most commercial filters last 30-45 days during summer due to desert dust and construction activity. After dust storms, inspect within 48 hours regardless of schedule. Outside of peak season, every 60-90 days is typically sufficient for most commercial environments.

When is the best time to schedule commercial HVAC maintenance for summer?

April or May — at least 4-6 weeks before temperatures consistently exceed 100°F. This gives your contractor time to find and fix any issues (low refrigerant, failing capacitors, worn belts) before the heat arrives. By mid-June, every HVAC company in Las Vegas is running emergency calls, and scheduling a routine tune-up becomes difficult. Getting ahead of the rush also means lower rates and better availability for any needed repairs.

What does a commercial HVAC tune-up actually include?

A thorough commercial tune-up should include: filter replacement and airflow measurement, condenser and evaporator coil cleaning, refrigerant charge verification with superheat/subcooling readings, electrical testing (amp draws, capacitor values, contactor condition), thermostat calibration and schedule review, condensate drain cleaning, belt and bearing inspection, and a written report documenting findings and recommendations for each unit.

How much does a commercial HVAC emergency repair cost in Las Vegas during summer?

Emergency commercial HVAC repairs during peak summer typically cost 50-100% more than the same repair during off-peak months. A compressor replacement that might run $2,500-$4,000 in spring can easily reach $4,000-$6,000 as an emergency call in July, factoring in after-hours rates, rush parts sourcing, and premium scheduling. The service call fee alone is often $300-$500 for emergency response. Preventive maintenance plans eliminate most of these emergencies.

Can I handle commercial HVAC maintenance in-house?

Facilities teams can handle basic tasks like filter replacements, clearing debris from around units, and monitoring thermostat schedules. However, refrigerant work requires EPA 608 certification, electrical testing requires trained technicians, and coil cleaning on commercial equipment requires commercial-grade tools and chemicals. Most building managers find that a combination approach works best: in-house staff handles weekly visual inspections and filter checks, while a licensed contractor performs quarterly or semi-annual technical service.

Keep Your Building Cool This Summer

Las Vegas commercial HVAC is not forgiving. The desert does not care about your occupancy schedule, your lease obligations, or your energy budget. But the buildings that stay comfortable and efficient through July and August all have one thing in common: their maintenance started in spring.

The Cooling Company provides commercial HVAC maintenance, emergency repair, and system optimization for businesses throughout Las Vegas, Henderson, and North Las Vegas. Our licensed technicians service rooftop units, split systems, and packaged equipment across offices, retail, restaurants, medical facilities, and multi-site portfolios.

Call (702) 567-0707 today to schedule your pre-summer commercial maintenance or ask about our maintenance plan options. The best time to prepare for a Las Vegas summer is right now.